A Comprehensive Guide to Types of Essay

May 23, 2022Premier ten Errors On -mail Order Star of the event – jetbride. com That you could Easlily Ideal Currently

May 24, 2022Variable Cost Per Unit Formula, How to Calculate, Examples

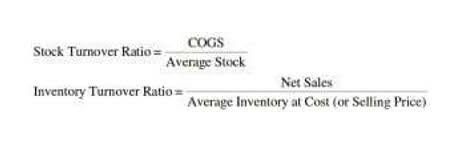

Quantity sold methods are the techniques a business uses to analyze, forecast, or manage the quantity of goods sold. This can be done using a variety of methods including how to calculate cost per unit economic order quantity (EOQ), SKU analysis, or demand forecasting. Additionally, a lower cost per unit can also identify gaps in internal efficiencies.

Latest tips to improve ecommerce logistics

Variable costs on the other hand are business costs that change over a period of time. These are based on multiple internal and external factors and the overall performance of the business. Some of the common examples of variables costs in logistics are – indirect labour costs, electricity bills, cost of raw materials, taxes, transportation costs, etc.

- This cost per unit indicates that any car sold above $1200 will be a profitable deal.

- To reduce these costs, analyze your business operations and identify areas for adjustments.

- Reducing inventory holding costs can be done by optimizing the inventory levels and selling off excess inventory.

- They also provide insights into the cost structure and financial implications of different business scenarios, enabling informed decisions.

- PTL services costs are lesser that full truckloads, delivery is on time and there are lesser instances of loading and unloading ensuring lesser scope of damage.

- If product demand (and the coinciding production volume) exceed expectations — in response, the company’s variable costs would adjust in tandem.

- However, the increment in the rate to 6 percent would increase the per unit variable cost by Rs 0.226 per unit.

Step 2 – List All Costs and Corresponding Values

Technology and automation can balance sheet improve efficiency and minimize errors, reducing total production expenses and hence, the cost per unit. This financial metric is integral to understanding what it costs you to manufacture, deliver, or sell a unit of your product and price it accordingly. It does that by handling repetitive and labor-intensive tasks performed by human workers. Typically, the price per unit exceeds the cost per unit to ensure profitability for the company. Cost per unit represents the expenses a company bears to produce one unit of a product. On the other hand, price per unit is the amount a customer pays to buy that product.

Flowspace vs. ShipBob: Which Fulfillment Partner is Right for You?

If the cost per unit is too high, your business may need to consider raising the price. Or, you might want to put in place cost-cutting measures to sustain profitability. If the selling price falls below the production cost, the company may incur losses. However, below the break-even point, such companies are more limited in their ability to cut costs (since fixed costs generally cannot be cut easily). The higher the percentage of fixed costs, the higher the bar for minimum revenue before the company can meet its break-even point.

Lowering expenses related to logistics

![]()

It can help cut down labor costs, space requirements, warehousing expenses, and the need for special equipment. Therefore, entering into negotiations with your suppliers to source them at a lower cost and favorable payment terms is imperative. You can seek flexible options like volume discounts, extended payment terms, and trade Bookstime credit arrangements. Labor costs that differ based on location, skill level, and demand also affect your final cost per unit. This is because labor charges, material spending, and tax regulations affecting the final cost of production may differ from country to country. You can use the price per unit formula to determine which size offers a better value for money.

Cost Per Unit: How to Calculate and Compare the Average Cost of Each Unit of Output

This analysis is essential in identifying where cost savings can occur and monitoring the impact of efficiency improvements in business operations. Cost Per Unit Analysis may indicate that the cost per unit is decreasing over time due to economies of scale. However, if the analysis fails to consider the declining quality of the smartphones or the negative impact on customer satisfaction, the company may face long-term consequences. Remember, comparing cost per unit is not a one-size-fits-all approach. It requires careful consideration of the specific industry, business model, and cost structure. By conducting a comprehensive analysis and utilizing appropriate cost allocation methods, businesses can make informed decisions and optimize their operations.